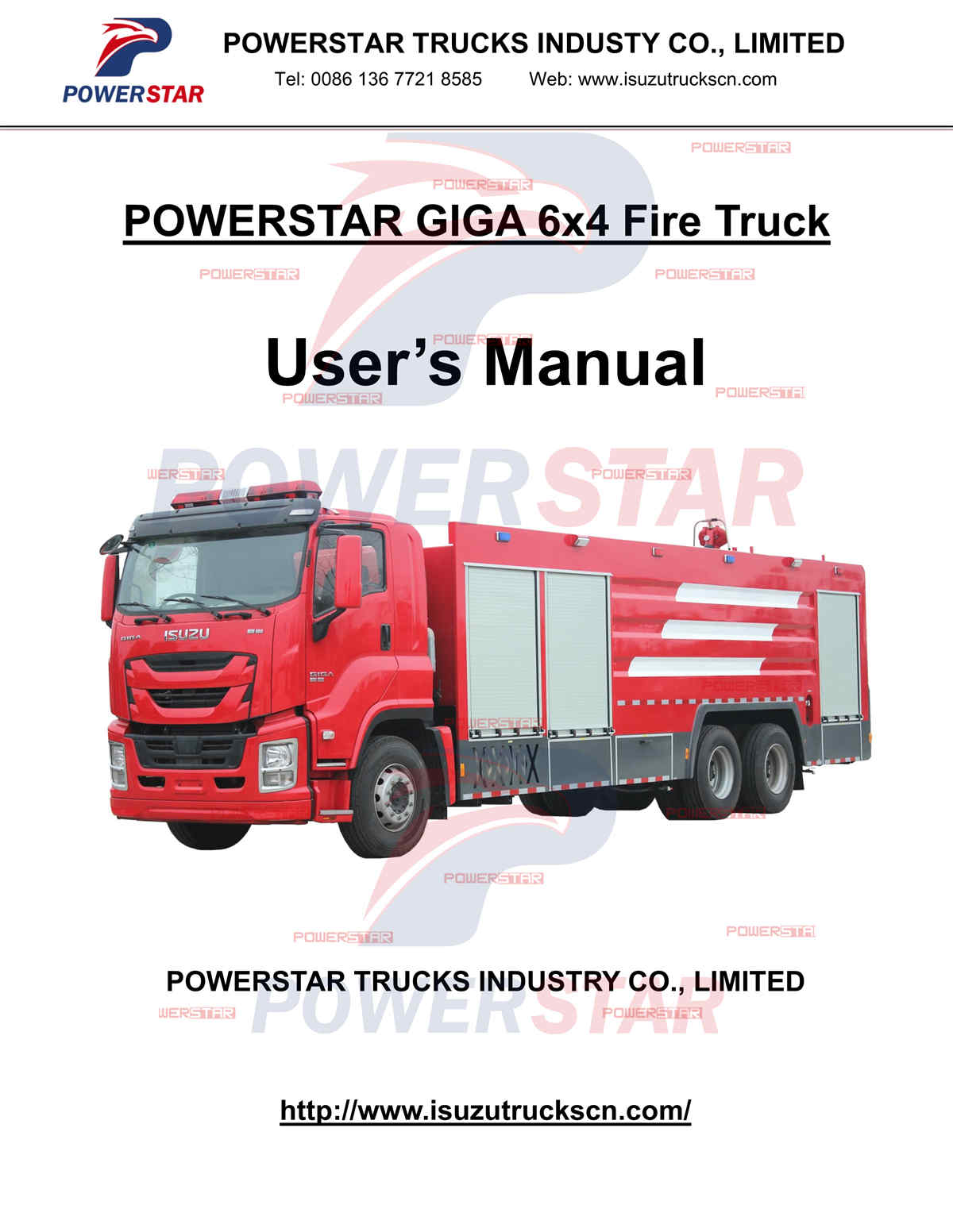

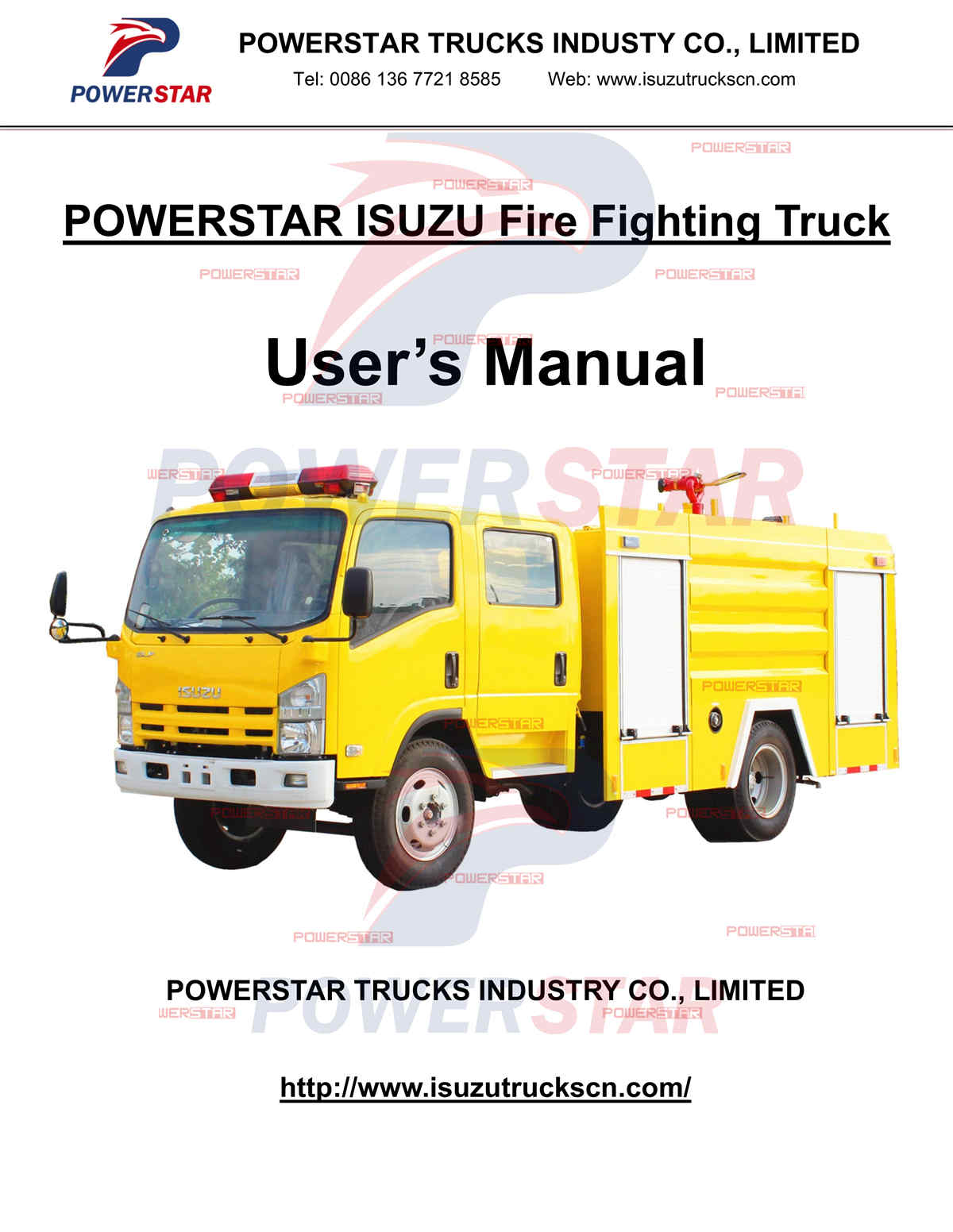

POWERSTAR Trucks Catalogue for Isuzu vehicles refers to the products catalog of Isuzu produced and export by professional Isuzu manufacturer. Isuzu trucks are high-quality and reliable commercial vehicles used worldwide in a wide range of industries and purposes. The following is a detailed introduction to all Isuzu truck product catalogue: Diversified models: POWERSTAR Catalogue contains Isuzu trucks of various types and specifications to meet customers in different fields and needs. These models include Isuzu fire trucks, Isuzu garbage compactor trucks, Isuzu fire trucks, Isuzu sewage trucks, Isuzu dump trucks, Isuzu tank trucks, ISUZU crane trucks, Isuzu bucket trucks, etc. High quality and reliability: Isuzu trucks are known for their excellent quality and reliability. Each model undergoes strict quality control and testing to ensure its stability and durability in various working environments, And you can get all details from POWERSTAR company. Powerful system: POWERSTAR produced and export Isuzu truck is equipped with an advanced power system and an efficient engine and transmission system to ensure that the truck has good power and efficient fuel economy during transportation. Safety and comfort: All kinds of customized Isuzu trucks focus on occupant safety and comfort. It provides safety equipment that meets international standards, such as ABS braking systems, air bags, rigid body structures, etc., while designing a comfortable and user-friendly cab space to provide a good driving experience. Flexible configurations and customization options: The Isuzu truck product catalog offers a variety of configurations and options that can be customized according to customer needs, such as different body lengths, load capacities, box types and special equipment installations to meet various industries and uses needs. Means when you get contact with us today, and you will get what you need today! Easy maintenance and after-sales service: POWERSTAR company is committed to providing customers with comprehensive after-sales support and services. Isuzu trucks are designed with ease of maintenance and repair in mind, while providing professional maintenance personnel and supply chain systems to ensure fast and efficient after-sales service and parts supply. Below page showing POWERSTAR previous export case and customers visiting to our factory, also trucks inspection: Below page showing ISUZU garbage compactor trucks, Isuzu refuse compactor trucks, Isuzu rear loader garbage trucks: Below page showing Powerstar produced and export Isuzu fire trucks, Isuzu water fire truck, Isuzu foam fire truck, Isuzu rescue fire trucks: Below page showing Isuzu aerial platform trucks, including Isuzu telescopic model aerial platform truck and Isuzu manlifter trucks: Below page showing Powerstar export Isuzu crane trucks, Isuzu loader crane trucks, with optional crane brand as Palfinger, UNIC, HIAB, XCMG, POWERSTAR

View More